How to Choosing a correct APTC Heater ? And why choosing a APTC Heater ?

Introduction of PTC heater principle

PTC heater is a device that uses the semiconductor heating principle of PTC ceramic material to achieve heating. PTC ceramic materials have low resistance at low temperatures. When the current through the heater is too large, the temperature will rise, the material will undergo phase change, and the resistance will increase sharply, thereby effectively controlling the heating temperature and achieving the heating effect.

Advantages of PTC heaters:

Rapid heating

Temperature stable

Efficient use of energy

Technical advantages

PTC chip is the core component of PTC heater. We jointly develop with first-line chip manufacturers: Ceramics are dense, with fine grains and uniform structure, and have higher mechanical properties and voltage resistance; Special surface processing ensures good contact and heat transfer with the heat dissipation metal; The optimized R-T curve makes a single chip more powerful; The current impact stability ratio is small, which can reduce the fluctuation of the power grid and reduce the configuration of the vehicle circuit; It can be applied to vehicles with different voltage platforms, and the highest voltage can meet the design requirements of 1500VDC; Long-term aging power attenuation is less than 5%

Our Technology research and development

In the early stages of product design, CAE simulation analysis is performed on the structural parts to improve the reliability of forward development.

We did Flow resistance analysis Thermal analysis Force analysis as below

Adjust the core heating layout to ensure uniformity of air outlet temperature

For Air PTC Heater we called APTC Heater

Reliability and safety design The PTC

protection level is IP67 and is equipped with a breathable valve to effectively prevent internal chip breakdown and short circuit;

Breakdown voltage DC1180V;

Built-in two-stage temperature controller to prevent PTC from dry burning;

PTC continuous dry burning time>500h, durability test>2000h;

PTC cold state impulse current is not greater than 2.5 times the rated current;

It can realize time control and temperature control function to achieve energy saving effect;

Products meet EU E-Mark export standards;

The plastic parts used meet the vertical burning V-0 level and horizontal burning HB level requirements in GB/T 2408 "Determination of Plastic Combustion Performance - Horizontal Method and Vertical Method"; Other non-metallic parts meet the Class A requirements in GB 8410 "Combustion Characteristics of Automotive Interior Materials".

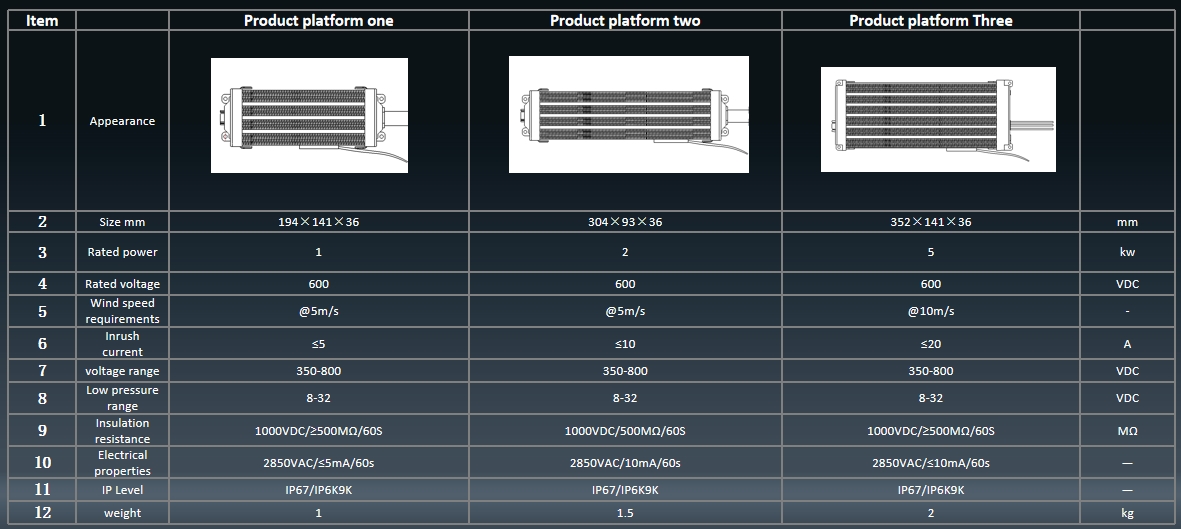

You can choosing the correct version of the PTC Heater